Products

Categories

Top Products

COntact US

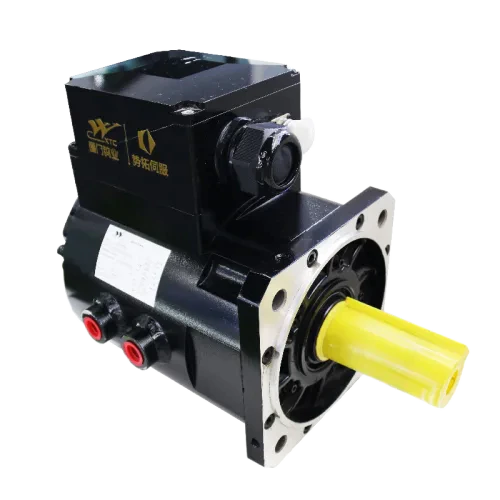

Product Title

Air-Cooled Servo Motor

Production Details

Structure

A servo motor is a type of electric motor that can rotate at a precise angle to a specific position. To do this task, a servo motor consists of:

• Stator: The stator is the stationary part of the motor, made of a coil of wire.

• Rotor: The rotor is the rotating part of the motor, made of a permanent magnet.

• Controller: The controller is the part that supplies power to the motor and controls the speed and position of the rotor.

Product advantages

Servo motors offer a host of advantages, primarily due to their closed-loop control system, which makes them highly precise and efficient. They outperform standard and stepper motors in many high-performance applications, from robotics to CNC machining.

Applications

Because of their precision, servo motors are used in a wide range of devices.

• CNC machines: For accurately controlling the positioning of cutting tools.

• Automated manufacturing: In assembly lines and packaging machinery that require high accuracy and repeatability.

• Aerospace: For controlling aircraft components, such as flaps and landing gear.

• Hobby projects: Small servos are used in radio-controlled cars, airplanes, and toy robots.

Solution

Solution 1 – Precision Servo Control for General Machinery

Servo motors enable dynamic speed regulation from 0 to 3000 rpm in just 0.1s, ensuring optimal coating quality for epoxy, wear-resistant layers, and concrete polishing. With adaptive torque control, servo systems maintain stable power output even on slopes or uneven terrain. Their synchronous multi-unit coordination further improves construction efficiency by over 30% compared with conventional motors, making them ideal for large-area industrial projects.

Solution 2 – High-Precision Servo Solution for Rubber & Plastics

With closed-loop feedback and ±0.001 mm precision, servo motors ensure precise screw metering, extrusion control, and injection molding. They deliver up to 90% system efficiency, cutting energy consumption by 40%–90% compared to hydraulic drives. Their ability to output high torque at low speeds and maintain constant torque at high speeds ensures smooth operation for both extrusion and high-speed injection. Digital control minimizes mechanical transmission components, lowering maintenance frequency and downtime across the entire production line.

Solution 3 - Intelligent Servo Drive for Industrial Stirring

Servo motors provide precise control of position and speed, guaranteeing uniform mixing quality for chemicals, pharmaceuticals, food, and metallurgy applications. Their fast response allows real-time speed or direction adjustment based on process needs. The system automatically optimizes power output based on load conditions, reducing energy waste, noise, and vibration. This makes servo-driven stirring systems ideal for industries with strict demands for consistency, precision, and green production.

Solution 4 – Servo Optimization for Modern Vulcanizing Machines

Solution 4 – Servo Optimization for Modern Vulcanizing Machines

Servo-driven vulcanizing systems replace traditional hydraulic or pneumatic actuators in critical steps such as mold closing, pressure control, cavity positioning, and opening/closing speed adjustment. Compared with hydraulic drives, servo systems deliver higher accuracy, reduced oil leakage, faster response, and substantial energy savings. Implementing servo technology requires proper system matching, mechanical adaptation, and coordinated closed-loop control. As servo + IoT becomes mainstream, vulcanizing machines will benefit from predictive maintenance, real-time monitoring, and self-optimizing production processes—driving the industry toward intelligent, sustainable manufacturing.

Main Technical Parameters

| Motor model | Torque (Nm) | Rated Speed(rpm) | Current(A) | Rated Power(kW) | Level of efficiency(%) | Frequency(Hz) | Moment of inertia(Kg-m²) |

| HN seris | 8.4-2674 | 1000-2000 | 1.8-729.3 | 0.9-369 | 86.79-97.3 | 67/100/113/133 / 150 | 0.83-518.4 |

| GN seris | 4-90 | 1000-6000 | 8.9-383.8 | 88.8-96.6 | 67/100/150/200/267/333/400 |

Main Technical Parameters

| Motor model | Torque (Nm) | Rated Speed(rpm) | Current(A) | Rated Power(kW) | Level of efficiency(%) | Frequency(Hz) | Moment of inertia(Kg-m²) |

| HN seris | 8.4-2674 | 1000-2000 | 1.8-729.3 | 0.9-369 | 86.79-97.3 | 67/100/113/133 / 150 | 0.83-518.4 |

| GN seris | 4-90 | 1000-6000 | 8.9-383.8 | 88.8-96.6 | 67/100/150/200/267/333/400 |

Common Materials Of Motor

Copper

Copper can be drawn into flat shapes to form rectangular winding wires. Rectangular winding wires are integral components in compact and high-performance applications like electric vehicle motors, EV power trains etc.

Steel

Silicon steel offers good shielding properties against electromagnetic interference. Therefore, it is useful in equipment where the radiation needs minimizing, such as medical instrumentation or transport systems like railroads.

Cast Iron

Cast iron is a good choice for an engine block. It is easily sand cast, easy to machine, capable to resist piston wear quite well, and inexpensive as a material.

Silicon steel sheet

The silicon steels are produced in two forms, highly textured grain-oriented alloys and alloys in which the grains are not oriented. Grain orientation is carried out to align the magnetic easy axis.

Solution 4 – Servo Optimization for Modern Vulcanizing Machines

Solution 4 – Servo Optimization for Modern Vulcanizing Machines